The is a simple and versatile 12 stage water level indicator circuit which will show you the current water level in the tank. This circuit can be used for general purposes. This circuit generates an alarm when the water level is below the lowest level of L1 and also when the water just touching the highest level L12. The circuit is designed to display 12 different levels. However, the level display can be increased or decreased depending on the level of resolution required. This can be done by increasing or decreasing the number of levels of the metal strip detectors (L1 through L12) and related components.

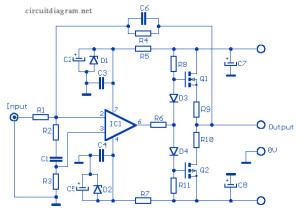

In this water level indicator circuit, the diodes D1, D2 and D13 act as a half-wave rectifier. Rectified output is filtered using a capacitor C1 through C3 respectively.

Initially, when the water level is below the L1 strip, supplying electrical oscillation frequency is not transferred to the diode D1. Thus the low output and LED1 does not light. Also, because the base voltage of the transistor T1 is low, it is in a state of cut-off and the collector voltage is high, which enables to produce melody IC1 (UM66) and the alarm is sounded.

When the water is just touching the L1 level detector strip, the oscillation frequency of the supply transferred to the diode D1. This straightening supply voltage and positive DC voltage developing capacitor C1, which is lit LED1. At the same time the base voltage of the transistor T1 becomes high, which makes forward bias and collector voltage falls to near ground potential. Disabling IC1 (UM66) and the alarm is inhibited.

Depending on the quantity of water present in the tank, which shows the level of the corresponding LED lights up. It thus showing medium level of water in the tank with a bar-chart style.

When the water in the tank just touching the highest level detector lines L12, DC voltage developed in capacitor C2. This makes it possible to produce a melody IC1 (UM66) and the alarm sounds again.

The post 12 Stage Water Level Indicator appeared first on Electronic Circuit Diagram.